Description

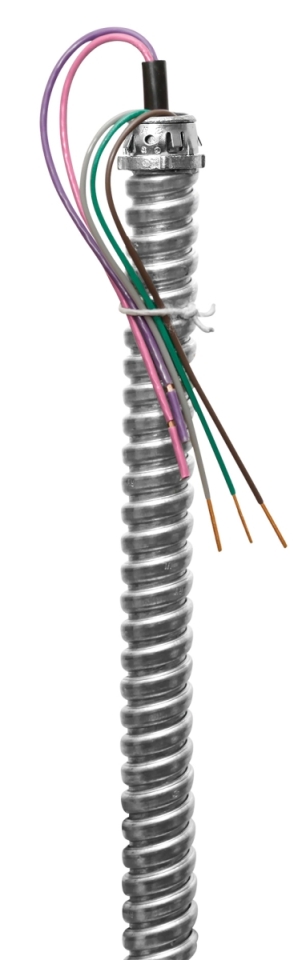

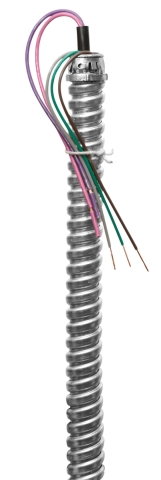

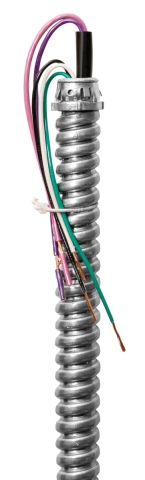

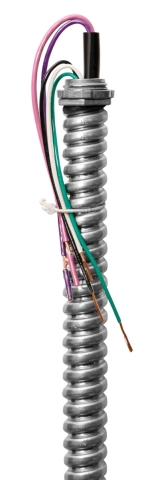

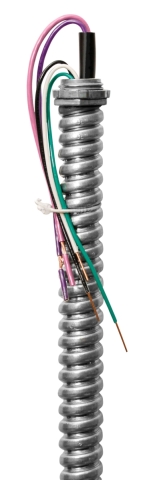

Our Illumination Control Fixture Whip (ICFW) is an integral component for illumination and control of all lighting systems. The ICFW can be used in new or retrofit construction for lighting systems operating at 120/277 VAC, meets all UL and NEC standards for combining power and lighting circuits with Class 2 or Class 3 control circuits within the same fixture whip, and is the cost-effective solution that saves the contractor time and labor when compared to buying and terminating expensive five conductor MC Cable or making a homemade solution at the job site.

The ICFW is easily integrated into the architecture of a building using LED luminaires or fluorescent luminaires with dimming ballast and digital controls to:

- Optimize lighting at all times when used with an independent room controller for daylight harvesting as an energy management solution to reduce energy consumption.

- Operate in compliance with "timed" daily personnel and warehouse schedules.

- Control lighting operations used in combination with occupancy sensors for commercial and industrial applications.

BENEFITS

- UL Listed. File Number E87199.

- Meets the requirements of the 2023 National Electrical Code, Article 300.3(C)(1), Section 725.136(I)(1), 725.139(A) through (D)(1) and California Title 24 Lighting Controls, Articles 130.1(A)(B)(C)(D)(E).

- Meets UL and NEC Articles for combining Power / Lighting Circuits and the Class 2 or Class 3 Control Circuits all within the same Fixture Whip.

- Easy to install and wire. Installation is familiar to electrical contractors and is less prone to installation error.

How Does it Differ from EPCO's Standard 3/8" or 1/2" Fixture Whip?

EPCO's Standard Fixture Whip is intended to exclusively connect the Line Voltage Conductors of an LED Driver or Ballast to the incoming Power Conductors within an Electrical Junction Box (Class 1 Circuit).

Why is it Necessary to have a Different Fixture Whip Configuration than our Standard Whip when a Luminaire will Utilize Wireless Lighting Controls?

- Wireless Lighting Controls use Relay Modules that can be attached to the outside of an electrical junction box with a nipple.

- The connection(s) of the low voltage conductors from the dimmable ballast or LED driver are intended to go through the Junction Box, and through the nipple and into the Lighting Control Relay Module to receive controller commands.

- When the Electrical Contractor wants to use a single pre-fabricated Fixture Whip to control a luminaire with control features.

TYPICAL APPLICATIONS

- LED and Fluorescent Dimming

- Smart Buildings

- Daylight Harvesting Systems (saves energy)

Contact the EPCO Inside Sales Department at 800.336.1976 or sales@engproducts.com for more specific information on other connector types available.